Optical Fiber Testing

1. Chromatic Dispersion System

The system provides both Chromatic and Polarization Mode Dispersion (PMD) offering unparalleled measurement of speed and compact design.

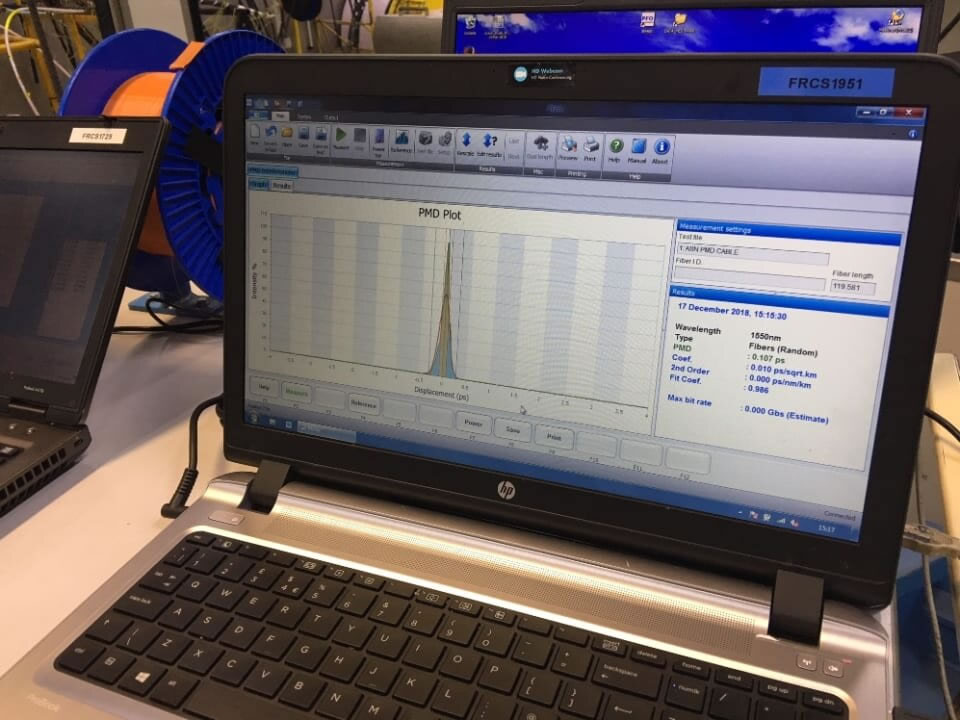

2. PMD4000 Polarisation Mode Dispersion Measurement System

The PMD4000 is a unique and complete PMD test solution for fiber and cable manufacturing.

3. PK2800 Fiber Analysis System

These products are used by optical fiber, cable and component manufacturers to measure fiber transmission properties that are critical to the proper functioning of both single-mode and multimode optical communications networks

Quality Control Of Outdoor Fiber Optical Cable

1. Attenuation Testing By OTDR

The cable and fiber attenuation will be tested during each steps of cabling from bear fibers , loose tube twisting to cabling according to the IEC 60793 standard . The attenuation of 1310 nm ≤ 0.36db/km and 1550 nm ≤ 0.22db/km, and the cable length will be tested as well .

2. Water Penetration Testing

The cable will be tested the water penetration performance . IEC standard requests the 1m length cable no water leakage from outside within 24 hours .

3.High And Low Temperature Cycling Testing

Time of testing:

Transition from 0°C to -40°C:2hours;

Time per each durationat-40°C:8 hours;

Transition from-40°C to +85 °C;4hours;

duration at +85°C:8hours;

Transition from +85°C to 0°C:2hours

Standard Of IEC 60794:

Attenuation variation for reference value (the attenuation to be measured before testat+20±3°C) w 0.05 dB/km

4.Repeated Bending Testing

5. Cable Bending And Torsion Testing60794 Standard

No additional attenuation ≤ 0.05db/km and no damage to outer jacket and inner elements in addition of 2m sample length and ± 180 degrees .

6. Optical Cable Vibration Testing

The cable and fiber comprehensive performance should be stable during vibration 10 mins in 50HZ frequency .

7. Cable tensile strength testing

The fiber attenuation should stay in safe range during pulling cable by specific tension strength of different cables .