Understanding MPO and MTP Connectors for High-Density Cabling

This article provides an in-depth technical overview for engineers, network designers, and procurement managers, exploring the specifications, key distinctions, and practical applications of MPO and MTP connector technology in modern network deployments.

The Foundation: Multi-Fiber Connectivity

The core innovation of MPO technology is the consolidation of multiple optical fibers into a single, compact connector interface. Instead of managing dozens of individual duplex connectors, technicians can connect 8, 12, 16, or even 24 fibers simultaneously. This a significant leap in efficiency, reducing installation time, minimizing human error, and enabling a much denser physical network layout.

What is an MPO Connector?

MPO is the baseline connector design, developed to IEC 61754-7 and TIA-604-5 standards. It utilizes a push-on-pull-off latching mechanism and houses multiple fibers in a rectangular ferrule. This design facilitates mass fiber connections essential for parallel optics transceivers operating at speeds of 40Gbps and beyond.

What is an MTP Connector?

An MTP connector is a registered trademark of US Conec and represents a high-performance MPO connector. While fully compliant and interoperable with standard MPO connectors, MTP connectors incorporate several patented design enhancements aimed at improving mechanical stability and optical performance over the long term. These enhancements include:

- Floating Ferrule: The MTP connector’s ferrule can float to maintain physical contact between mated pairs, even under mechanical load.

- Elliptical Guide Pins: The use of elliptical-shaped guide pins and tighter manufacturing tolerances reduces debris generation and ferrule damage during mating cycles.

- Removable Housing: The MTP housing can be removed for easier performance testing, polarity changes, and ferrule cleaning in the field.

- Metal Pin Clamp: A robust metal pin clamp design prevents guide pin breakage and ensures precise alignment.

For mission-critical applications where reliability and repeated reconnections are expected, the engineering advantages of the MTP connector often justify its selection over a standard MPO connector.

Core Technical Specifications for System Design

Deploying an MPO/MTP cabling system requires careful consideration of several key parameters to ensure network integrity and interoperability. Choosing the correct configuration from the outset prevents costly troubleshooting and redesigns later.

1. Connector Gender: Male vs. Female

Unlike traditional simplex or duplex connectors, MPO/MTP connectors have a gender, which is critical for establishing a valid connection.

- Male Connector: Features two metal guide pins protruding from the ferrule. These pins ensure precise alignment with the opposing connector.

- Female Connector: Features two corresponding holes to receive the guide pins from a male connector.

A fundamental rule of MPO/MTP connectivity is that a male connector must always mate with a female connector. Attempting to connect two male or two female connectors will either fail or result in physical damage. Typically, active equipment like transceivers and internal adapter ports on cassettes feature female connectors, requiring male-ended patch cords for the connection.

2. Polarity Schemes (TIA-568 Standard)

Polarity refers to the mapping of optical fibers from one end of a cable to the other. An incorrect polarity scheme will result in a failed link, as transmitters will be connected to other transmitters instead of receivers. The TIA-568 standard defines three primary methods for MPO/MTP systems:

- Type A (Straight-Through): Fiber 1 at one end maps to Fiber 1 at the other end in a direct, 1-to-1 relationship. This is achieved with a “key up” to “key down” adapter configuration. Type A trunk cables are often used in conjunction with polarity-managing cassettes for breakout applications.

- Type B (Reversed or Crossed): Fiber 1 at one end maps to Fiber 12 (in a 12-fiber system) at the other end. This is achieved with a “key up” to “key up” adapter configuration. Type B assemblies are commonly used for direct connections between 40G/100G parallel optics transceivers.

- Type C (Flipped Pairs): Fiber 1 at one end maps to Fiber 2 at the opposing end, and Fiber 2 maps to Fiber 1. This pair-wise flipping continues across the cable. Type C is less common but is used for specific structured cabling architectures and to connect to certain legacy systems.

Network architects must define and maintain a consistent polarity scheme throughout a link to ensure proper communication between transceivers.

3. Fiber Count and Application Alignment

MPO/MTP connectors are available in various fiber counts, with the choice depending on the specific application.

- 8-Fiber: Optimized for 40G (4x10G) and 100G (4x25G) parallel optics (QSFP+, QSFP28), which use 4 transmitting and 4 receiving fibers. This is an efficient choice as it utilizes all fibers in the cable.

- 12-Fiber: The most common and versatile option. While it can be used for 40G/100G applications (leaving 4 fibers unused), its primary use is as a backbone or trunk cable for aggregation, breaking out into 6x duplex LC connectors.

- 24-Fiber: Used for high-density backbone links and emerging 100G/400G applications that utilize a 10x10G or 8x50G architecture. They are effective in consolidating pathways and reducing the overall cable count.

Practical Applications in Modern Networks

The versatility of the MPO/MTP platform allows it to be deployed across various network environments. As a manufacturer of a wide array of fiber optic cable and connectivity solutions, ZTO Cable sees these connectors primarily used in three key areas.

Data Center Interconnects

In large-scale data centers, MPO/MTP trunk cables form the backbone of the entire physical layer. They are used to create high-bandwidth links (100G, 400G, and beyond) between core switches and routers in spine-and-leaf architectures. Pre-terminated trunks can be rapidly deployed, connecting to MPO/MTP adapter panels or fanout cassettes in distribution frames.

High-Density FTTH and Telecom Networks

While often associated with data centers, the density benefits are also highly valuable in telecommunications. Central offices and headends utilize MPO/MTP connectors to manage the massive fiber counts required for Fiber-to-the-Home (FTTH) rollouts. These connectors are integral to the FTTH equipment ecosystem, streamlining connections within Optical Distribution Frames (ODFs) and splitter cabinets.

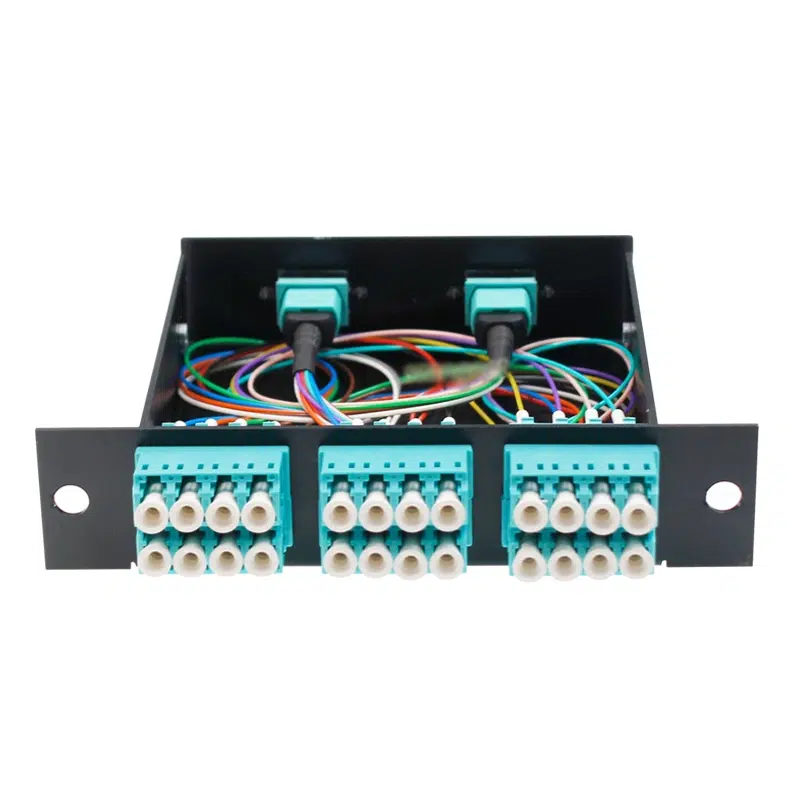

Breakout and Fanout Configurations

One of the most powerful use cases for MPO/MTP is in “breakout” or “fanout” scenarios. A single 12-fiber MTP trunk cable can be connected to a cassette or fanout hydra cable that breaks out into 6 duplex LC connectors. This allows a high-density trunk to provide connectivity to multiple lower-speed servers, switches, or patch panels, significantly simplifying cable management behind the rack.

Conclusion: Partnering for Performance

MPO and MTP connectors are no longer a niche technology but a fundamental building block for any network that requires scalability, density, and high performance. Understanding the nuances of gender, polarity, and connector type is crucial for designing and deploying a reliable, future-proof cabling infrastructure. Whether implementing a new data center fabric or expanding an FTTH network, leveraging a well-designed MPO/MTP system saves installation time, reduces operational complexity, and provides a clear pathway for future upgrades.

ZTO Cable, with over 20 years of manufacturing experience, provides a comprehensive portfolio of high-quality ODN accessories, including MPO/MTP patch cords, cassettes, and adapter panels, alongside our extensive range of fiber optic cables. Our solutions are engineered for reliability and performance in demanding global networks. For technical consultations or to discuss your specific project requirements, please contact our team of experts.