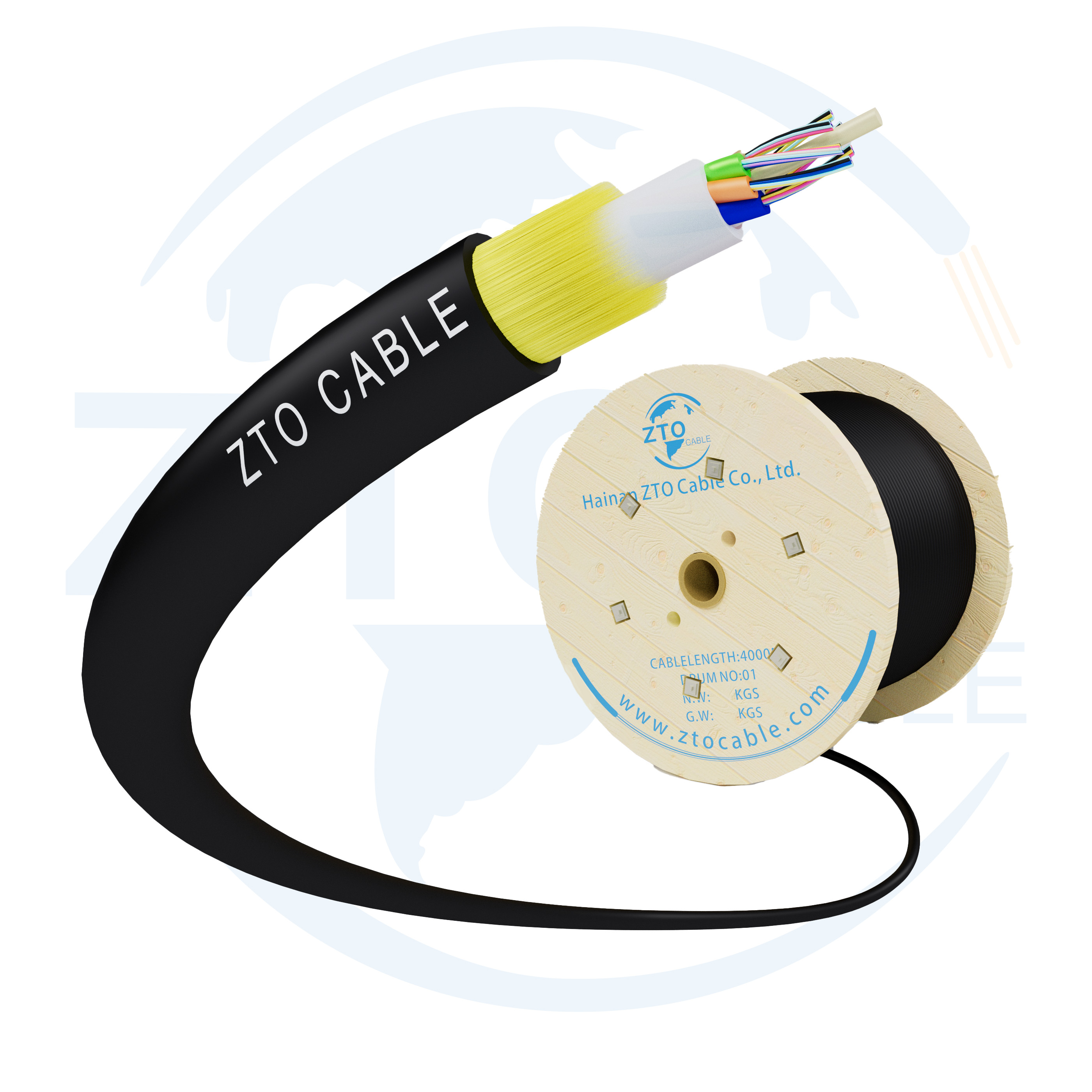

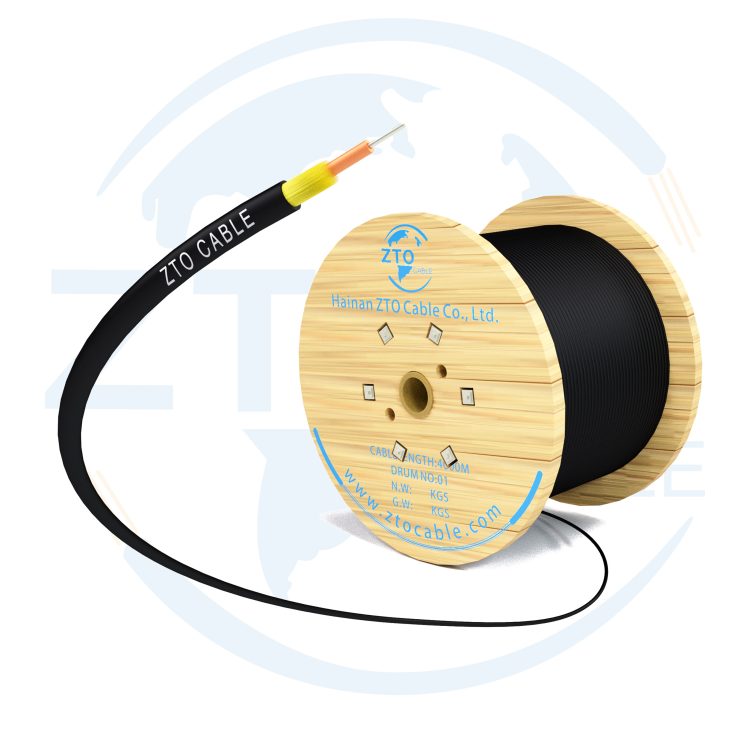

Independent Research And Production Of Optical Cables

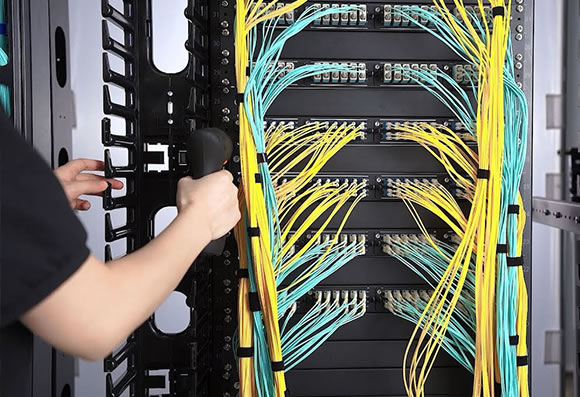

ZTO Fiber Optic Cable Company is a national high-tech enterprise specializing in the research and development, production and sales of various optical fibers, optical cables, passive optical devices, and wiring products. We can give customers more favorable prices because of the factory’s direct sales so we can bring more profits to customers.

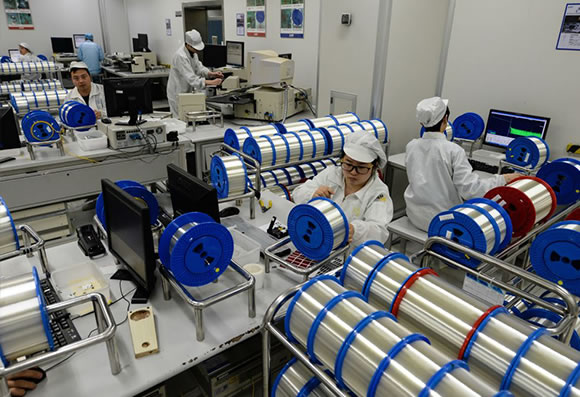

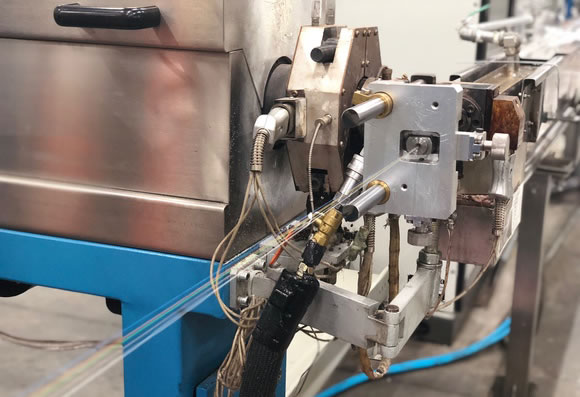

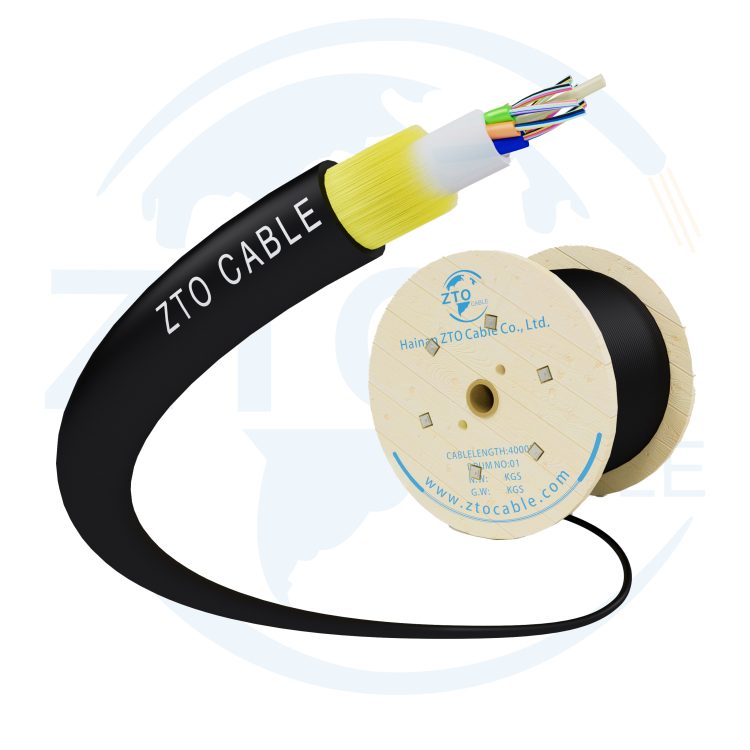

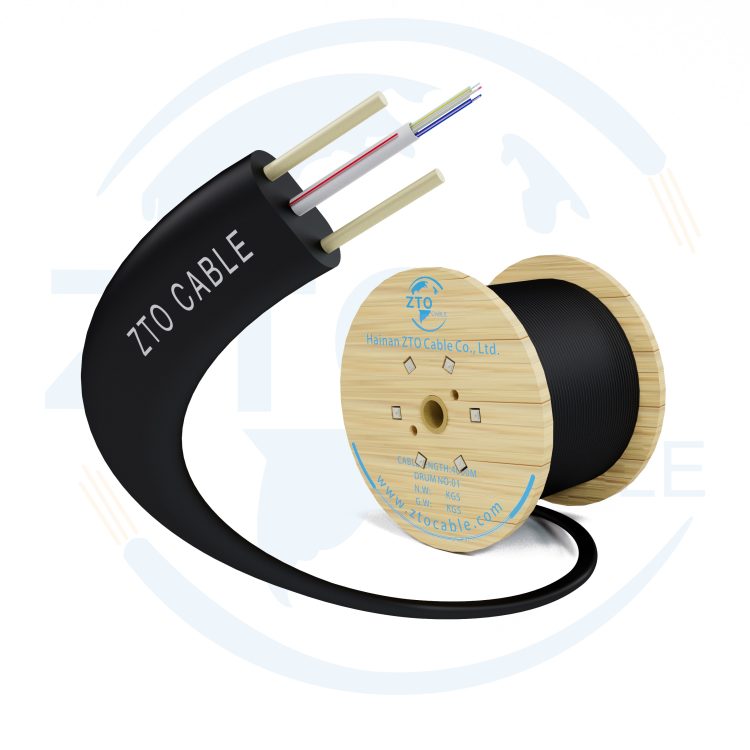

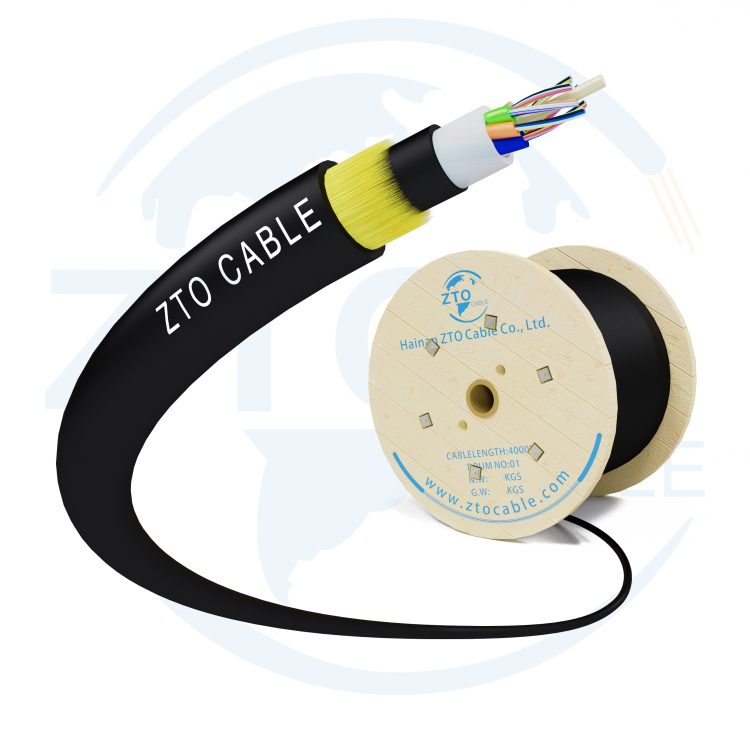

R&D Fiber Optical Cables

With 34 cable production lines, annual production capacity over 900,000 km

ODN FTTH Accessories

One-stop supplier of FTTH accessories, such as splitter, pigtail, distribution box, patch panel, ODF, joint box , etc.

About Us

Hainan ZTO Cable Co., Ltd.

Hainan ZTO Cable Co., Ltd. is a wholly-owned subsidiary of ZTO Cable Group. We are located in Hainan Free Trade Island, which was established in response to the call of the country to vigorously build the Hainan Free Trade Port. ZTO Cable has more than 20 years of professional R&D and production experience in optical cables and was awarded a national high-tech enterprise in 2010. There are more than 300 employees, including 80 professional and technical personnel, more than 10 senior engineers, and 30 engineers. So far, more than 60 national, and provincial invention patents and utility model patents. At the same time, there is a professional optical cable technical service team, which has more than 1,000,000 kilometers of domestic and foreign optical cable testing, installation supervision, and technical service experience.

Projects

Our successful projects recently, more are underway

ZTO ADSS Cables Were installed In Quito Ecuador

ZTO ADSS Cables Were installed In Quito Ecuador ZTO Cable Won The…

ZTO Cables Delivered To Myanmar And Customers Are Testing The Attenuation

ZTO Cables Delivered To Myanmar And Customers Are Testing The…

ZTO Cable is waiting for installed in Argentina

ZTO Cable is waiting for installed in Argentina Argentina is…